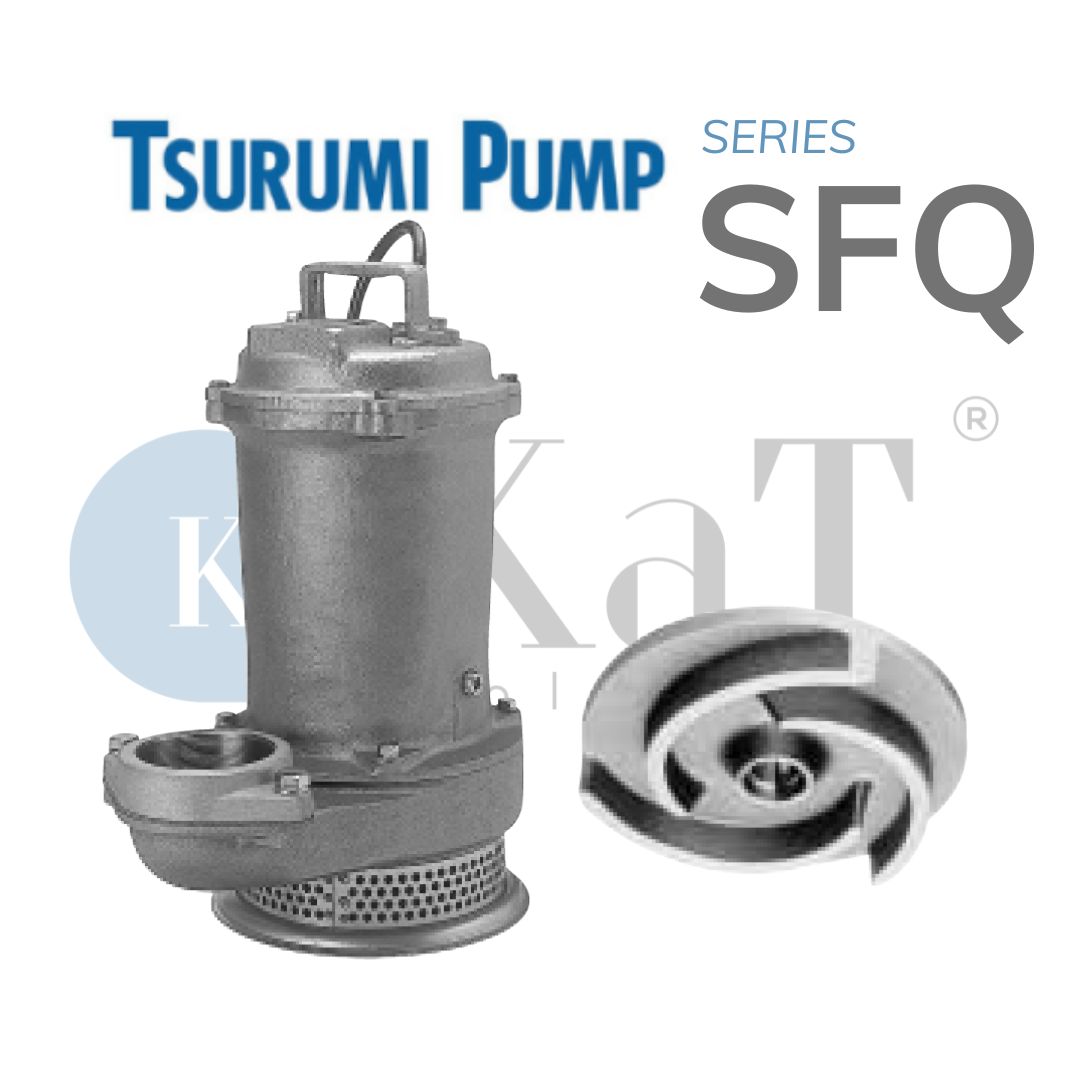

Submersible pump Tsurumi SFQ Series

Tsurumi Submersible Wastewater Pump SFQ Series

Power: 0.4–3.7 kW, Voltage: 380V.

The SFQ Series is constructed entirely of stainless steel and designed for handling corrosive wastewater. It features a multi-stage open impeller driven by a 2-pole motor, enabling the pump to lift wastewater from deep underground or transport it to elevated locations.

Tsurumi SFQ series submersible wastewater pumps are the ideal solution for applications involving highly corrosive liquids. All wetted parts are entirely manufactured from 316 stainless steel, enabling the pump to withstand harsh operating conditions in environments such as chemical processing, mining, and construction. Notably, models with power ratings of 5.5 kW and above come equipped with a sealed pressure relief port to protect the pump shaft from excessive pump pressure. Moreover, models ranging from 5.5 kW to 11 kW offer flexible mounting options, either with a filter support bracket or a pump support bracket, to suit various installation requirements. With these superior features, the Tsurumi SFQ series is a reliable and efficient choice for handling corrosive liquids.

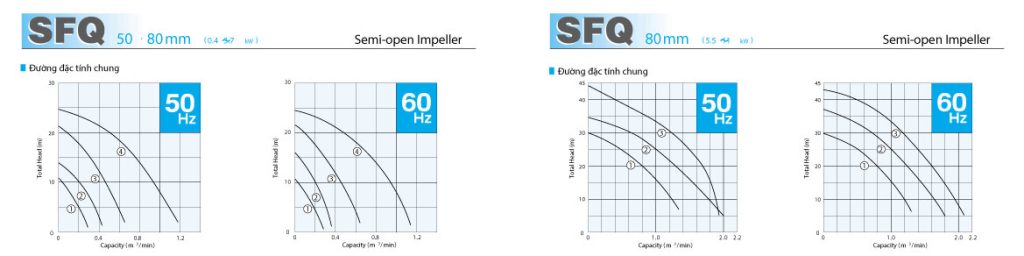

Technical Specifications of Tsurumi SFQ Series Submersible Wastewater Pumps

-

Discharge Nozzle Diameter: 50 mm, 80 mm

-

Water Temperature: 0 – 40°C

-

Liquid Types: Treated wastewater, clean water, rainwater

-

Impeller: Horizontal spiral impeller

-

Motor Shaft: Made of 316 stainless steel

-

Pump Casing: Constructed from cast iron

-

Mechanical Seals: Dual SiC seals with an Oil Lifter cooling system

-

Motor: 2-pole, 2850 RPM

-

Insulation Class: F (up to 155°C)

-

Power Range: 0.4 – 3.7 kW, Voltage: 380V

List of Tsurumi SFQ Series Pump Models

| Model | Công suất

(kW) |

Đường kính

xả (mm) |

Cột áp tối

đa (m) |

Lưu lượng tối

đa (m³/phút) |

Trọng lượng

(kg) |

Chiều dài

cáp (m)) |

| 50SFQ2.4 | 0.4 | 50 | 10 | 0.3 | 15 | 6 |

| 50SFQ2.75 | 0.75 | 50 | 15 | 0.5 | 18 | 6 |

| 50SFQ21.5 | 1.5 | 50 | 20 | 0.7 | 22 | 6 |

| 65SFQ22.2 | 2.2 | 65 | 25 | 1.0 | 30 | 8 |

| 65SFQ23.7 | 3.7 | 65 | 30 | 1.2 | 38 | 8 |

| 80SFQ25.5 | 5.5 | 80 | 35 | 1.5 | 50 | 10 |

| 80SFQ27.5 | 7.5 | 80 | 40 | 1.8 | 65 | 10 |

| 80SFQ211 | 11.0 | 80 | 45 | 2.2 | 80 | 15 |

Corrosion Resistance Characteristics of the Tsurumi SFQ Series

All metal components in contact with the liquid are fabricated from either cast stainless steel (SCS14) or 316 stainless steel (SUS316). These stainless steel materials offer high strength, excellent corrosion and oxidation resistance—especially when exposed to various liquids. They not only ensure the durability and longevity of the product but also prevent leaks or contamination caused by inferior materials. Additionally, stainless steel’s high gloss and ease of cleaning make it ideal for applications with strict hygiene and food safety requirements. Using these high-quality materials ensures outstanding performance, durability, safety, and quality for the end user.

Corrosion-Resistant Mechanical Seals

The Tsurumi SFQ series submersible wastewater pumps are equipped with high-performance corrosion-resistant components such as silicon carbide (SiC) mechanical seals, fluoro rubber gaskets, and stainless steel parts.

High-Performance Chemical Pumping

The SFQ product line is the ideal choice for transferring or discharging corrosive liquids in chemical plants, pharmaceutical facilities, laboratories, etc. Valves in this series are specially designed to withstand harsh chemicals and corrosive environments, ensuring safe and efficient operation. Moreover, SFQ valves offer precise flow control, allowing users to accurately manage the liquid transfer and discharge processes.

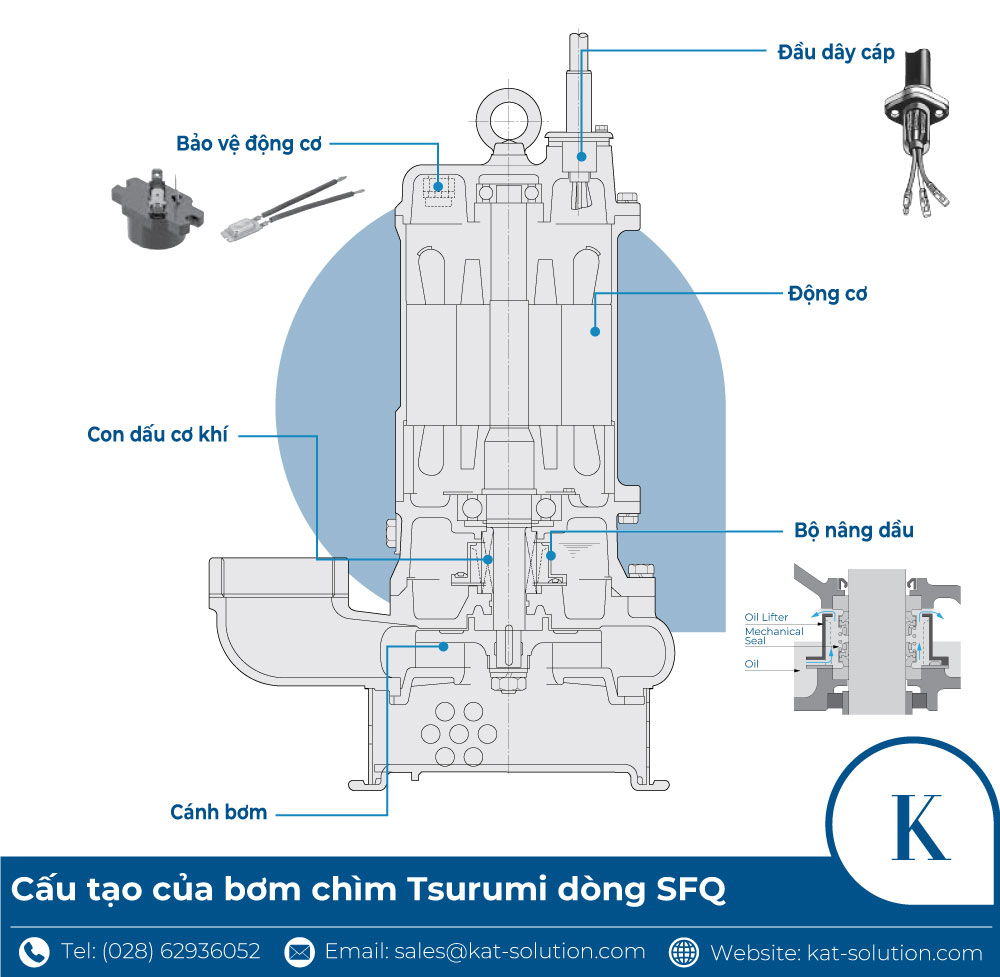

Components of the Tsurumi SFQ Series Submersible Wastewater Pump

-

Motor Protection Unit Integrated thermal protection is provided for motors up to 7.5 kW. This protection unit is installed within the motor housing and will automatically disconnect the motor circuit if overheating or electrical/mechanical faults occur. For 11 kW motors, three thermal protection devices are installed on each coil of the 3-phase motor. These devices are connected in series, with wiring routed outside the motor. If any coil’s temperature exceeds the threshold, the bimetal inside the protection unit will trip and immediately cut off the motor’s power.

-

Mechanical Seals The pump features dual mechanical seals with silicon carbide (SiC) faces, equipped with an oil chamber to completely eliminate the risk of corrosion, wear, or clogging—thereby preventing potential seal failures.

-

Pump Impeller A spiral impeller is mounted on the top of the pump housing. This impeller, along with a large flow passage within the housing, allows the pump to efficiently handle coarse solids with particle sizes of up to 35 mm.

-

Oil Lifter The Oil Lifter is developed as an effective lubrication system for the mechanical seals. Utilizing centrifugal force from the impeller, the Oil Lifter continuously supplies lubricant—even when oil levels drop below the specified threshold—ensuring effective lubrication, cooling, and stable sealing, thereby extending maintenance intervals.

-

Sealed Motor Configuration The Tsurumi SFQ series pump features a sealed motor configuration that effectively prevents wastewater from entering the motor and other critical components. This design ensures long-term safety and reliability, even under harsh operating conditions, providing users with peace of mind regarding continuous, durable operation.

Tsurumi Pump Distributor in Vietnam

KaT Solution is an authorized distributor of Tsurumi pumps, offering a full range of genuine products from Tsurumi with complete warranty coverage.

Services Provided by KaT Solution:

-

Expert Consultation: With over 25 years of experience, KaT Solution offers free technical consultations to recommend the best solutions for your specific needs.

-

Comprehensive Support: Beyond being a distributor, KaT Solution provides technical guidance and support from the initial stages of selection through the entire service life of the product.

KaT Solution is dedicated to delivering reliable, high-quality products, backed by thorough after-sales service to ensure optimal performance and customer satisfaction.