Submersible pump Tsurumi B Series

Tsurumi Submersible Wastewater Pump B Series. Power: 0.75 – 110 kW, Voltage: 380V.The B Series is designed for wastewater treatment applications in industrial zones, factories, export processing zones, large restaurants, and hotels. It ensures high durability, long service life, and continuous operation without clogging.

Tsurumi B-series pumps are basic heavy-duty, submersible sewage and wastewater pump sproviding excellent solids matter passing capability with reliable operation. The B-series pumps have accumulated various track record and know-how in a wide range of industrial and water treatment applications for many years. Using a channel impeller, they are designed to minimize trouble due to clogged solids and fibrous matter in pumped fluids.

The B-series offers a wide lineup of discharge bores ranging from 50 – 300 mm and motor outputs of 0.4 – 75 kW, and comes in a variety of models including high head type and single-phase BP models that can handle high volume pumping demand. Particularly, the high head type pumps can satisfy the needs of the building equipment market that is oriented to saving energy and conserving water, and fit other high head market applications. Moreover, the pumps can be used with Tsurumi’s guide rail fitting device that facilitates installation and maintenance (except for BP models).

Tsurumi pumps come packed with a number of original technologies we have developed and honed over years of research, including an anti-wicking cable, motor protector, dual inside mechanical seals with silicon carbide faces and Oil Lifter. Highly reliable and durable, Tsurumi pumps are designed and built for sound quality and prolonged continuous operation.

Product Models in the Tsurumi B Series Pump Range

The Tsurumi Submersible Pump B Series offers a wide range of models categorized by discharge diameter as follows:

Discharge Diameter: 50 – 100 mm

| Discharge Bore (mm) |

Model | Motor Output (kW) |

Phase | Starting Method |

Solids Passage (mm) |

| 50 | 50B2.4S | 0.4 | 1-phase | Capacitor Start | 35×22 / 35×18 |

| 50 | 50B2.4 | 0.4 | 3-phase | D.O.L. | 35×22 / 35×18 |

| 50 | 50B2.75S | 0.75 | 1-phase | Capacitor Start | 21×25 |

| 50 | 50B2.75 | 0.75 | 3-phase | D.O.L. | 45×20 / 51×23 |

| 50 | 50B2.75H | 0.75 | 3-phase | D.O.L. | 21×25 |

| 80 | 80B21.5 | 1.5 | 3-phase | D.O.L. | 49×41 / 49×35 |

| 100 | 100B42.2 | 2.2 | 3-phase | D.O.L. | 47×53 / 47×46 |

| 100 | 100B43.7 | 3.7 | 3-phase | D.O.L. | 81×53 / 81×47 |

| 100 | 100B43.7H | 3.7 | 3-phase | D.O.L. | 35×62 / 35×55 |

| 100 | 100B45.5 | 5.5 | 3-phase | D.O.L. | 40×51 / 40×43 |

| 100 | 100B47.5 | 7.5 | 3-phase | D.O.L. | 40×61 / 40×54 |

Discharge Diameter: 150 – 500 mm

| Discharge Bore (mm) |

Model | Motor Output (kW) |

Phase | Starting Method |

Solids Passage (mm) |

| 150 | 150B63.7 | 3.7 | 3-phase | D.O.L. | 70 / 55 |

| 150 | 150B47.5H | 7.5 | 3-phase | D.O.L. | 75 / 70 |

| 150 | 150B47.5L | 7.5 | 3-phase | D.O.L. | 60 / 50 |

| 150 | 150B411 | 11 | 3-phase | Star-Delta | 75 |

| 150 | 150B415 | 15 | 3-phase | Star-Delta | 75 |

| 150 | 150B422 | 22 | 3-phase | Star-Delta | 75 |

| 150 | 150B437 | 37 | 3-phase | Star-Delta | 40×72 / 40×50 |

| 200 | 200B47.5 | 7.5 | 3-phase | D.O.L. | 80×60 / 100×50 |

| 200 | 200B411 | 11 | 3-phase | Star-Delta | 68×60 / 65×58 |

| 200 | 200B415 | 15 | 3-phase | Star-Delta | 70×60 / 69×60 |

| 200 | 200B422 | 22 | 3-phase | Star-Delta | 75 |

| 200 | 200B422H | 22 | 3-phase | Star-Delta | 75 |

| 200 | 200B437 | 37 | 3-phase | Star-Delta | 40×77 |

| 200 | 200B455 | 55 | 3-phase | Star-Delta | 40×110 / 45×90 |

| 250 | 250B611 | 11 | 3-phase | Star-Delta | 80×68 / 80×58 |

| 250 | 250B415 | 15 | 3-phase | Star-Delta | 73×64 |

| 250 | 250B622 | 22 | 3-phase | Star-Delta | 90×90 / 90×76 |

| 250 | 250B430 | 30 | 3-phase | Star-Delta | 75×80 / 76×76 |

| 250 | 250B437 | 37 | 3-phase | Star-Delta | 63×80 / 65×76 |

| 250 | 250B445 | 45 | 3-phase | Star-Delta | 45×70 / 45×68 |

| 250 | 250B455 | 55 | 3-phase | Star-Delta | 45×70 / 45×68 |

| 250 | 250B475 | 75 | 3-phase | Star-Delta | 35×70 / 35×78 |

| Discharge Bore (mm) |

Model | Motor Output (kW) |

Phase | Starting Method |

Solids Passage (mm) |

| 300 | 300B615 | 15 | 3-phase | Star-Delta | 140×90 / 140×60 |

| 300 | 300B622 | 22 | 3-phase | Star-Delta | 140×76 / 127×76 |

| 300 | 300B630 | 30 | 3-phase | Star-Delta | 130×115 / 140×76 |

| 300 | 300B637 | 37 | 3-phase | Star-Delta | 140×100 / 140×65 |

| 300 | 300B445 | 45 | 3-phase | Star-Delta | 60×90 / 70×76 |

| 300 | 300B645 | 45 | 3-phase | Star-Delta | 130×85 / 134×76 |

| 300 | 300B655 | 55 | 3-phase | Star-Delta | 105×90 / 110×98 |

| 300 | 300B475 | 75 | 3-phase | Star-Delta | 60×80 / 65×90 |

| 350 | 350B822 | 22 | 3-phase | Star-Delta | 156×100 / 160×90 |

| 350 | 350B630 | 30 | 3-phase | Star-Delta | 190×95 / 200×70 |

| 350 | 350B637 | 37 | 3-phase | Star-Delta | 190×130 / 200×100 |

| 350 | 350B645 | 45 | 3-phase | Star-Delta | 130×90 / 140×78 |

| 400 | 400B822 | 22 | 3-phase | Star-Delta | 156×109 / 160×90 |

| 400 | 400B637 | 37 | 3-phase | Star-Delta | 190×130 / 200×100 |

| 400 | 400B645 | 45 | 3-phase | Star-Delta | 175×128 / 175×100 |

| 400 | 400B655 | 55 | 3-phase | Star-Delta | 145×110 / 175×100 |

| 400 | 400B675 | 75 | 3-phase | Star-Delta | 130×100 / 140×90 |

| 500 | 500B1037(50Hz) | 37 | 3-phase | Star-Delta | 225×100 |

| 500 | 500B1237(60Hz) | 37 | 3-phase | Star-Delta | 225×100 |

| 500 | 500B855 | 55 | 3-phase | Star-Delta | 175×140 / 175×80 |

| 500 | 500B675 | 75 | 3-phase | Star-Delta | 130×120 / 130×100 |

| 500 | 500B875(60Hz) | 75 | 3-phase | Star-Delta | 190×80 |

Discharge Diameter: >500 – 800 mm

| Discharge Bore (mm) |

Model | Motor Output (kW) |

Phase | Starting Method |

Solids Passage (mm) |

| 600 | 600B1255 | 55 | 3-phase | Star-Delta | 220×100 |

| 600 | 600B1085 | 85 | 3-phase | Star-Delta | 210×85 |

| 700 | 700B1265 | 65 | 3-phase | Star-Delta | 300×85 |

| 700 | 700B1275 | 75 | 3-phase | Star-Delta | 300×85 |

| 800 | 800B1290 | 90 | 3-phase | Star-Delta | 300×90 |

| 800 | 800B14110 | 110 | 3-phase | Star-Delta | 310×90 |

Technical Specifications of Tsurumi B Series Pumps

-

Discharge Diameter: 50, 80, 100, 150, 200, 250, 300–800 mm

-

Water Temperature Range: 0–40°C

-

Liquid Type: Wastewater, raw water, water containing solids

-

Impeller Type: Open impeller made of cast iron

-

Motor Shaft Material: Stainless Steel 416

-

Pump Body: Cast iron construction

-

Shaft Seal: Dual mechanical seal (Silicon Carbide – SiC) with an Oil Lifter cooling system

-

Motor: 4-pole, 1450 RPM

-

Insulation Class: Class E (180°C) and F (155°C)

-

Power Output: 0.75–110 kW

-

Voltage: 380V

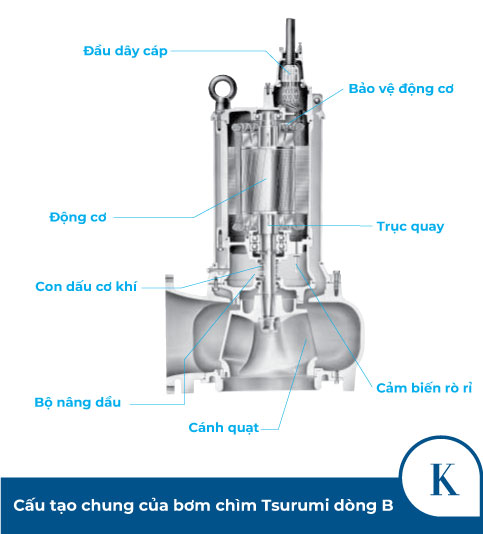

Construction of Tsurumi B Series Pumps

Anti-wicking Cable Entry

Prevents water incursion due to capillary action should the cable sheath be damaged or the end of cable submerged. Also prevents moist air from infiltrating the motor housing and condensation from forming inside the housing due to temperature differences between the housing and outside air.

Motor Protector

Circle Thermal Protector (7.5kW and below)Directly cuts the motor circuit if excessive heat builds up or overcurrent occurs in the motor.

Miniature Thermal Protectors (11kW and above)React to excessive heat caused by dry-running. The bimetal strip opens to cause the control panel to shut the power supply.

Water Jacket

(150B475 only)

The pump is equipped with a water jacket, around the motor frame. A portion of the pumped liquid is allowed to flow into the water jacket to cool the motor. This design feature permits the unit to operate at low water levels for extended periods of time.

Dual Inside Mechanical Seals with Silicon Carbide Faces

Isolated in the oil chamber where a clean, non-corrosive and abrasion-free lubricating environment is maintained. Compared with the water-cooled outside mechanical seal, it reduces the risk of failure caused by dry-heating and adhering matter. The silicon carbide provides 5 times higher corrosion, wear and heat resistance than the tungsten carbide. Rubber parts of the upper and lower fixing rings are made of NBR or FPM (FKM), which provides higher resistance to heat and chemicals.

Oil Lifter

Provides lubrication and cooling of the seal faces down to 1/3 of normal oil level, thus maintaining a stable shaft sealing effect and prolonging seal life longer. The Oil Lifter is Tsurumi original design.

Leakage Sensor

(18.5kW and above, excluding 150B422 and 200B422)

Detects flooding into the oil chamber that may occur in a worst case scenario. When flooding is detected, signals are sent to operate the indicator lamps through the external control panel.

Seal Pressure Relief Port

(11kW and above of 80 & 100mm bore, 22kW and above of 150mm bore, and 200B422)

Protects the mechanical seal from pump pressure. It also protects the seal face by discharging wear particles.

Single/Triple Oil Seals

Labyrinth Ring (150B475 only)

Used as a “Dust Seal”, single or triple oil seals protect the mechanical seal from abrasive particles. The labyrinth ring is equipped to provide a better countermeasure against wear caused by high pressure generated in the casing and improve the maintainability

Air Release Valve

Fitted on the water jacket or the pump casing to prevent the air lock. When air flows through the valve, the ball stays at the bottom, but when the pumped water starts to flow, the ball closes the outlet because of its buoyancy.

Mouth Ring & Wear Ring

(150B437 and 150B475 only)

Prevent wear in the pump casing and suction cover, resulting in reduced maintenance costs.

Applications and Fields of Use for Tsurumi B Series Submersible Wastewater Pumps

Tsurumi B series pumps, with their cast iron construction, are a reliable and versatile choice for various applications:

Wastewater Treatment

Tsurumi B pumps are extensively used in wastewater treatment plants, sewage treatment stations, and drainage systems for handling and processing wastewater effectively.

Industrial Applications

These pumps are ideal for handling industrial fluids, including pumping water from wells, factory wastewater, and related applications involving liquid or sludge handling.

Residential Applications

Tsurumi B series pumps are suitable for residential uses, such as pumping groundwater, household wastewater, swimming pool water, and other related applications.

Construction Projects

These pumps are widely employed in construction for dewatering tasks, including pumping wastewater from basements, drainage systems, and other related construction operations.

With exceptional durability, anti-corrosion properties, and the ability to perform continuously in harsh environments, Tsurumi B series pumps are among the top choices for wastewater pumping applications. Their reliability and robust performance minimize downtime and ensure long-lasting

Tsurumi Pump Distributor in Vietnam

KaT Solution is an authorized distributor of Tsurumi pumps, offering a full range of genuine products from Tsurumi with complete warranty coverage.

Services Provided by KaT Solution:

-

Expert Consultation: With over 25 years of experience, KaT Solution offers free technical consultations to recommend the best solutions for your specific needs.

-

Comprehensive Support: Beyond being a distributor, KaT Solution provides technical guidance and support from the initial stages of selection through the entire service life of the product.

KaT Solution is dedicated to delivering reliable, high-quality products, backed by thorough after-sales service to ensure optimal performance and customer satisfaction.